|

Cyclones |

|

|

|

Classifiers |

|

Air classification is a process of separating particles into groups or grades at cutpoints ranging from 10 mesh to sub-mesh sizes. Air classifiers complement screens in applications requiring cutpoints below commercial screen sizes and supplement sieves and screens for coarser cuts where the special advantages of air classification warrant it. |

|

|

Fabric Collectors |

|

The keys to a successful dust collection project are the selection of the most suitable type of filter media, housing design, materials of construction, air-to-cloth ratio as well as other important factors. Fisher-Klosterman, Inc. offers many types of collector designs, from standard baghouses and cartridge collectors to highly custom engineered equipment. Our experienced engineering staff will ensure that you receive the best selection for your application. New technologies in filter media such as pleated filter elements, ceramic media, and laminated or coated filters can be used in many applications that were previously difficult to deal with effectively. |

|

|

Scrubbers |

|

In particulate scrubbers, dirty gas is forced at high velocity through a venturi where it collides with a scrubbing liquid. The liquid is atomized into tiny droplets which absorb particles through impaction and diffusion. The dirty water droplets are then removed in a cyclonic eliminator. The design of the scrubber must be carefully considered to ensure proper operation. At Fisher-Klosterman, Inc., we utilize numerous throat, water injection and separator designs to ensure that the scrubber you install is best suited for your process requirements. |

|

|

Packed Towers |

|

The packed tower or packed bed scrubber is used for the removal of gaseous, fume, or mist contaminants from an air stream. Packed Bed Scrubbers are relatively simple devices with potentially very complex chemistry. A well designed packed tower takes into consideration many factors and each application must be analyzed very carefully to assure chemical compatibility of all components and still achieve the desired results. Fisher-Klosterman, Inc. engineers are well prepared to solve even the most difficult scrubbing applications of multiple contaminants and can provide thoroughly integrated and smoothly functioning systems. For more information, contact our engineers directly. |

|

|

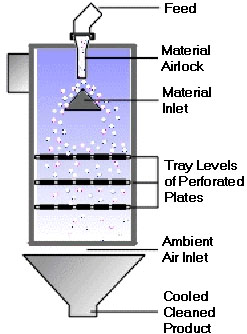

Econo-Flow Coolers |

|

A Multi-Stage, Fluid Bed Counterflow Cooler for the Efficient Cooling and Heat Recuperation of Free-Flowing Materials

|

|

|

자세한 제품 정보는 문의해 주십시요. |

Copyright (c) 2007 Shin Shin International. All rights reserved.