| Dry Solid Handling |

| Continuous Loss-In-Weight Feeder |

|

The Vibra Screw Continuous Loss-In-Weight Feeder provides unparalleled versatility in handling a broad range of feeding requirements. Feed rate from 20 pounds to 24,000 pounds per hour can be accomplished with accuracies of plus or minus 1/4-1% on a minute-to-minute basis at 2 sigma. Control of the feeder is through a microprocessor-based controller equipped with one million counts of resolution and exclusive disturbance elimination technology. Feeding devices can include pan or tube feeders, screw feeders and belt feeders. |

|

| Batch Loss-In-Weight Feeder |

|

Similar in design to the continuous weigh feeders, Vibra Screw's line of batch loss-in-weight feeders are capable of batches from ounces to tons, feeding materials from liquids and fine powders to fibrous or flaky materials. Control of batch size and feed time is provided through a unique control package that eliminates the effects of plant noise and the need for traditional vibration dampening devices. Batch accuracy of 1/4 to 1/2% or better can be achieved. |

|

| Control Packages |

|

Vibra Screw equips its continuous and batch weigh feeders with state-of-the-art control packages. All controllers incorporate user-friendly, menu-driven software. Membrane keypads and easy-to-read displays support a revolutionary concept of deciphering actual weight from plant vibration and electrical noise. Complete control packages are available not just to run Vibra Screw equipment but other equipment included in the system. Motor control panels and PLC controllers are available for turnkey operation. |

|

|

Bulk Bag Unloaders and Fillers |

|

Multi-Use Live Bottom Bin This unique, self-emptying bulk storage system combines a static cylindrical bin with the patented Vibra Screw Bin Activator in capacities from 3 to 1,200 cubic feet. Self-contained, pre-assembled and ready to install, the unit is extremely useful as a batching, portable or weigh bin, or where particle segregation is a problem. |

|

|

|

Pan And Tube Feeder/Conveyors Challenge these feeders with nearly any material, regardless of size, density, moisture content or temperature. They can be used as constant speed or variable speed conveyors using either electromechanical or electromagnetic drives. The key to the line's success is its low cost and simplicity of design. No moving parts ever touch your material. There are no augers, bearings, seals or other items which can degrade material or require replacement or maintenance. Select the size up to 100 feet long and rates up to 1,800 tons per hour. |

|

|

|

Vibrating Screens Vibra Screw provides a wide variety of highly efficient vibrating screens for applications that require cores scalping, multideck separation, or dewatering. Our screening units can be fitted with standard market grade or tensile bolting cloth, stainless steel mesh, nylon, or synthetic monofilament cloth, or bar screens. Your requests for special meshes and configurations can also be accommodated. |

| The Vibra-Blender This unique device employees the principle of controlled vibration to "fluidize" dry materials for rapid dispersion and continuous, high-speed blending of solids. With extremely low power requirements and minimal particle degradation, the Vibra-Blender approaches the efficiency of a batch blender. Choose from three modes with rates of up to 1,200 cubic feet per hour. |

|

|

Volumetric Feeders |

|

VersiFeeder Low Rate Screw Feeder Our VersiFeeder is the first volumetric feeder with a modular design, allowing one unit to adapt to the broadest range of feeding applications, including:

|

|

|

|

AccuFeedTM AccuFeed combines all the performance benefits of the VersiFeeder at lower cost and with off-the-shelf availability. Composite materials of construction are extremely durable and meet FDA and USDA requirements.These feeders offer rates to 650 cubic feet per hour, batch or continuous operation and feed accuracy of plus or minus 1-2%. |

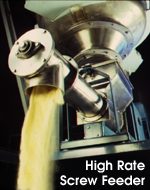

| Heavy-Duty High Rate Screw Feeders Vibra Screw's Heavy-Duty Feeders, available in 15 sizes, expand your volumetric metering capability to a maximum of 9,800 cubic feet per hour. Controlled vibration of the trough, screw and tube ensures accuracies of plus or minus 1-2% for hundreds of dry materials. Rugged construction allows operation 24 hours a day. |

|

| Specialized Screw Feeders Materials such a diatomaceous earth, lime, certain pigments, etc., spell trouble for even the toughest standard metering feeders. Our specialized screw feeders get the lumps out and let you meter materials that tend to pack and clump, especially when moist. Available in six sizes to handle rates from .28 to 600 cubic feet per hour. |

| Type HD Volumetric Belt Feeder The HD belt feeder operates in continuous service and handles large volumes of materials such as sawdust, ores, sand, lime and cement as well as chemicals and foods. These feeders work with any size of Vibra Screw Bin Activator, Live Bin, or Live Bottom Bin. Five models provide maximum feed rates of 70, 400, 1,200, 2,400 and 4,800 cubic feet per hour. |

|

|

자세한 제품 정보는 문의해 주십시요. |

Copyright (c) 2007 Shin Shin International. All rights reserved.